Question

Question: When both the studs are in contact in a screw gauge then a student finds that \({96^{th}}\) division...

When both the studs are in contact in a screw gauge then a student finds that 96th division of circular scale is in line with the reference line then the conclusion would be-

Solution

When both the studs are in contact it is said that no object is placed between two studs of screw gauge. Then we need to check for zero error that is positive zero error or negative zero error. Depending on the type of zero error the sign for zero error should be considered.

Complete step by step answer:

The studs are used to hold onto objects being measured tightly. The frame of the screw gauge consists of two studs. The smallest stud is known as the anvil and the largest stud is known as the spindle. The anvil is fixed, but the spindle rotates. The two studs are parallel to each other.

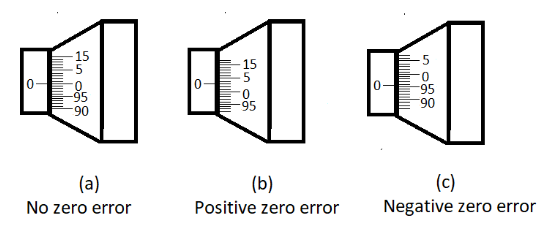

ZERO ERROR:- When the anvil and spindle of the screw gauge are made to touch each other, then the zero on the main scale should match with a zero on the circular scale. Then the screw gauge is said to have no zero error as shown in figure (a) .

However due to wear and tear or manufacturing defect the two zeros usually do not coincide with each other, then screw is said to have zero error. There are two types of zero error positive zero error and negative zero error. The zero mark of the circular scale is below the main scale line, then the error is said to be positive zero error as shown in figure (b). The zero mark of the circular scale is above the main scale line, then the error is said to be negative zero error as shown in figure(c).

In the question it has been mentioned that the 96th division of the circular scale is in line with the reference line then it is said to have negative zero error of 4 division. That is zero error,

ZC=−4

Then, final reading of screw gauge = MSR+CSR×LC−ZE …….(1)

Where, MSR= Main scale reading, CSR= Coincide scale reading and LC= Least count.

ZE= Zero error =−4.

Substituting in equation (1)

Final reading = MSR+CSR×LC−(−4)

Final reading = MSR+CSR×LC+4

Note: The zero error needs to be subtracted if the screw gauge is having positive zero error whereas the zero error needs to be added if the screw gauge is negative zero error. The conventional sign is + for positive zero error and − for negative zero error.