Question

Question: In a screw gauge, the zero of the main scale coincides with the fifth division of circular scale in ...

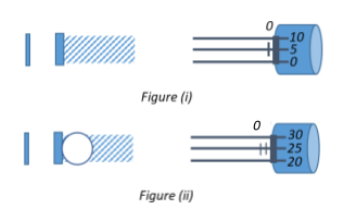

In a screw gauge, the zero of the main scale coincides with the fifth division of circular scale in figure (i). The circular divisions of the screw gauge are 50. It moves 0.5mm on the main scale in one rotation. The diameter of the ball in figure (ii) is:

A). 2.25mm

B). 2.20mm

C). 1.20mm

D). 1.25mm

Solution

We know that the pitch of the gauge is the distance by which it moves on the main scale in a single rotation. Use this to determine the least count of the circular scale, given that it has 50 divisions. From Figure (i) determine the zero error of the gauge, keeping in mind that the zero on the main scale is above the zero on the circular scale. Then deduce the main scale reading and the circular scale reading from Figure (ii) and use the previously found parameters to arrive at an appropriate diameter of the ball.

Formula Used:

Diameter: D=MSR+(LC×(CSR−Z))

Complete step-by-step solution:

We know that a screw gauge is an instrument that is used to accurately measure the diameter or thickness of spherical and cylindrical objects. The object to be measured is placed in between a fixed structure called anvil and is screwed into its place by a movable spindle. The spindle moves in response to the rotation of the screw of the circular scale. The thimble is usually rotated by hand, which in turn rotates the circular scale and calibrates it to an appropriate reading along with the main scale.

Before we begin to evaluate the problem given to us, let us understand the meaning of a few terms associated with measurements taken using a screw gauge.

The pitch of the screw gauge is defined as the distance moved by the spindle per rotation of the thimble, i.e.,

Pitch P=Number of rotationsDistance moved by gauge

Given that the gauge moves 0.5mm on main scale in one rotation of the screw,

Pitch P=10.5=0.5mm

The least count of the screw gauge is defined as the distance moved by the spindle when turned through one division of the main scale, i.e.,

Least Count LC=Number of divisions on circular scalePitch

We are given that the number of divisions on the circular scale is 50.

Therefore, least count LC=500.5=0.01mm

The zero error of a screw gauge is defined as the error when the zero line on the circular scale does not coincide with the zero on the main scale when the screw of the circular scale is fully tightened.

From Figure (i), we see that the zero of the main scale is above the zero of the circular scale and coincides with the 5th division of the circular scale.

Therefore, the zero error will be Z=5

Let us now look at Figure (ii).

We see that the main scale readingMSR is at 1mm,

And the circular scale readingCSR is at25

Therefore, the diameter of an object placed in between the spindle and the anvil can be given by:

D=MSR+(LC×(CSR−Z))

⇒D=1+(0.01×(25−5))=1+(0.01×20)=1+0.20=1.20mm

Therefore, the correct choice would be C. 1.20mm

Note: It is important to understand the sign convention behind zero error. The screw gauge is said to have a negative zero error if the zero of the main scale is below the zero of the circular scale. This is to account for the ahead-ness of the circular scale readings, which will be greater than the true actual value.

The screw gauge is said to have a positive zero error if the zero of the main scale is above the zero of the circular scale. This is done to account for the lagging of the circular scale readings, which will be lesser than the true value.

Thus, the zero error is subtracted or added from the circular scale readings as a means of calibrating the end result to an accuracy.