Question

Question: Assertion: Ductile metals are used to prepare thin wires. Reason: In the stress strain curve of du...

Assertion: Ductile metals are used to prepare thin wires.

Reason: In the stress strain curve of ductile metals, the length between the points representing elastic limit and breaking point is very small.

A. Both assertion and reason are correct and reason is the correct explanation for assertion.

B. Both assertion and reason are correct but reason is not the correct explanation for assertion.

C. Assertion is correct but reason is incorrect.

D. Both assertion and reason are incorrect.

Solution

The property by which any substance can be drawn in thin wires is called ductility. Some metals show this property to a significant level and some don’t. Stress-strain curve of a material gives us the indication of how a material behaves under deformation.

Complete step by step answer:

Ductility is a property by the virtue of which, a metal could be drawn into thin wires. This can be possible only when the metal can withstand huge deformations under the application of stress. Such metals are called ductile metals. Thus the statement “Ductile metals are used to prepare thin wires” is true.

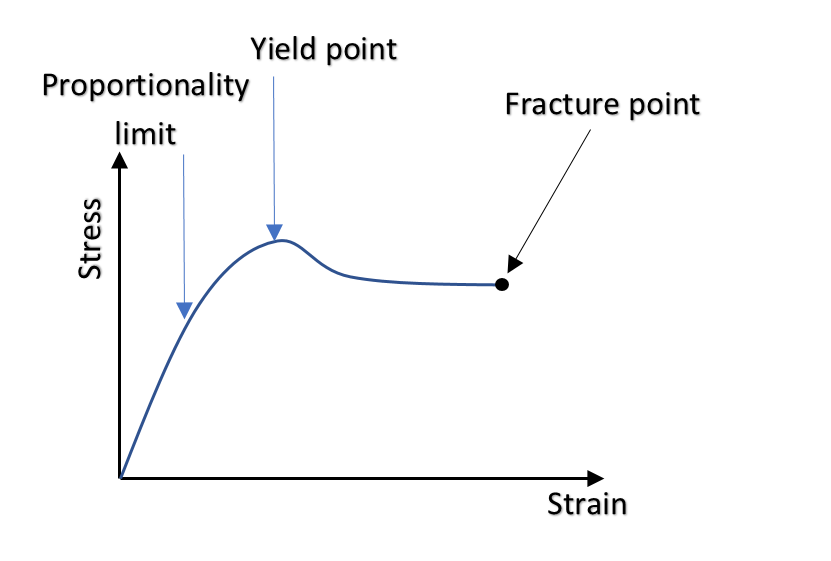

Now, the stress strain curve is the plot of how a material deforms under the application of a stress. The length of this curve directly corresponds to the amount of deformation that has occurred before fracture. Hence if the length of curve is more until fracture, then the material is said to be more ductile.

Hence, the assertion is correct but the reason is not correct. So option C. is correct.

Additional information:

There is another term called proportionality limit. This is a point up-to which a material follows Hooke’s law i.e. stress proportional to strain. After that the body starts deforming. This is also called elastic limit. After this point, the material will never regain its original shape and hence is said to undergo plastic deformation.

Note:

There is one more term related to this which is called Yield point. This is a point at which the internal molecules of the material are stretched to their maximum capacity. After this point, the internal bonds begin to break. Further if material is further loaded, it’ll ultimately lead to fracture.