Question

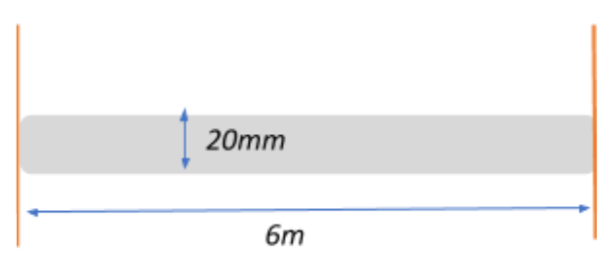

Question: A steel rod of length \(6.0\;m\) and diameter \(20\;mm\) is fixed between two rigid supports. The st...

A steel rod of length 6.0m and diameter 20mm is fixed between two rigid supports. The stress in the rod (in kgcm−2) is ____, when the temperature increases by 80∘C and a) The ends do not yield, b) The ends yield by 1mm.

(Take Y=2,0×106kgcm−2 and α=12×10−6 per ∘C)

A). 1587, 1920

B). 1920, 1587

C). 1000, 2000

D). 2000, 1000

Solution

Recall that since the rod is being heated up, it undergoes thermal stress. Use the relation(s) for thermal stress appropriately for each case. Note that in the first case the calculation is straightforward but in the second part where the ends of the rod yield by 1mm there is a change in length of the rod, which contributes to a linear strain caused by the thermal stress. Therefore, do not forget to account for this change in length and its subsequent implications on the stress experienced by the rod in this case. While calculating the change in length do not forget to calculate the net change as the rod may not actually increase in length to the extent we calculate.

Formula Used:

Thermal stress σ=YαT, where Y is Young’s modulus, α is the thermal coefficient of linear expansion and T is the temperature.

Increase in length due to an increase in temperature Δl=lαT, where l is the original length.

Linear strain or compressive strain ϵ=lΔl

Thermal stress accounting for the change in length of σ=Yϵ

Complete step-by-step solution:

Let us begin by defining what stress is and the kind of stress that we’re dealing with in the problem here.

Stress is the measure of internal forces acting on a body when an external force is applied to it. It is usually expressed as the force experienced by a unit cross-sectional area of a body on the application of an external force. The force applied is usually a deforming force that sets out to change the configuration of the body. The resistance offered by the body against this deforming force is called the stress experienced by the body.

Now, since the deforming force in this context is a change in temperature which changes the degree of hotness of the steel rod, we call this a thermal stress.

Now, let us begin our computation by listing out the parameters given to us.

We have the length of road l=6m=600cm, the diameter of the rod d=20mm=2cm,

temperature T=80∘C, Young’s modulus Y=2×106kg.cm−2 and the thermal coefficient of linear expansion α=12×10−6 per ∘C.

a). When the ends do not yield, that is when the length of the rod remains the same under an increase in temperature, the thermal stress in the rod is given by:

σ=YαT=(2×106)(12×10−6)(80)

⇒σ=1920kg.cm−2

b). When the ends of the rod yield by 1mm=0.1cm, that is when there is a change in length due to increase in temperature, the thermal stress on the rod is given as:

σ=Yϵ where ϵ=lΔl is the linear strain in the rod.

The total change in length due to the increase in temperature given by:

Δl=(lαT–0.1)=[(600)(12×10−6)(80)]−0.1=0.576–0.1=0.476cm

Therefore, the linear strain on the rod

ϵ=lΔl=6000.476=7.93×10−4

Thus, the thermal stress of the rod when the ends yield is given by:

σ=Yϵ=(2×106)(7.93×10−4)=1.58667×103=1587kg.cm−2

Therefore, the correct option would be: B. 1920, 1587.

Note: Note that we call the linear strain as the compressive strain through the rod ends up expanding. This is because the linear strain is caused by the thermal stress whereas the compressive strain is caused by the rod in response to the linear strain and is equivalent in magnitude. This is obvious because the rod exerts forces to prevent its expansion, by means of which it is in fact trying to compress the rod to hold off expansion caused by the thermal stress incident on it.

Also, do not forget to always maintain consistency in the units that define the parameters given to us. This is important in order to avoid unnecessary discrepancies that arise as a result of the inconsistency in the system of units we have used while computing, which most often results in an undesirable final solution.