Question

Question: A slightly conical wire of length L and radii \({r_1}\)and \({r_2}\) is stretched by two forces appl...

A slightly conical wire of length L and radii r1and r2 is stretched by two forces applied parallel to length in opposite directions and normal to end faces. If Y denotes the young's modulus then the elongation of the wire is

(A)2πr1r2YFL

(B)πr1r2YFL

(C)πr1r2Y2FL

(D)πr1r2Y4FL

Solution

Here, the total length of the conical wire before the extension is L and the r1and r2 are the radii of the conical wire. We are going to find the elongation of the wire when it was stretched by two equal and parallel forces acting in opposite directions. Young’s modulus is defined as the ratio of stress due to the applied load to longitudinal strain. We are going to derive the elongation of the wire with the young’s modulus formula.

Complete answer:

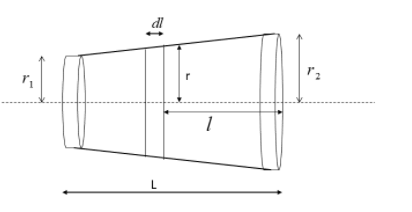

From the above figure, the radius r can be calculated as given by,

r=r1+L(r2−r1)l

Where l -length from one end of the wire at the radius r

L - the total length of the wire before elongation

The force acting on both sides is equal but opposite in direction. The elongation of the wire can be calculated at the point radius r

From young’s modulus formula,

Y=strainstress

stress=AF

Where F - force applied

A - cross sectional area of wire of radius r

strain=dlΔdl

Where Δdl- change in length

dl- original length

Therefore young’s modulus becomes,

Y=dlΔdlAF

Δdl=AYF.dl

Δdl=πr2YF.dl

Substituting the value of radius r in the above equation, we get

Δdl=π(r1+L(r2−r1)l)2YF.dl

Integrating on both sides with limits from0to L, we get the net elongation is given by

∫Δdl=0∫Lπ(r1+L(r2−r1)l)2YF.dl

Net elongation=YπF(r1+L(r2−r1)l)(Lr2−r1)−10L

=(Lr2−r1)1×YπF×(−r21+r11)

=(r2−r1)×YπFL×r1.r2(r2−r1)

Net elongation=r1r2YπFL

From the above derivation, the elongation of the wire =r1r2YπFL

Note: The elongation means the material length is to be increased when it is subjected to tensile force acted axially in the material. The elongation of any material depends on the same material properties like density, ductility, etc., and the most important is the tensile force acting on the material. The elongation of material under stress is calculated in the percentage of elongation.